|

|

last update 22/03/2000

topics: GEET, alternate Fuel,

Reactor |

| project: started: finished: description: |

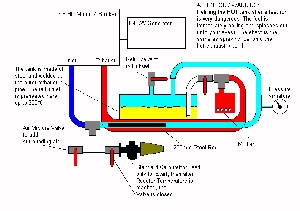

GeetGenerator 05 / 1999 in process as i saw paul pantone`s experiments on his webpage, i was fascinated and wanted to test the small engine concept. i ordered the geet plans ( 6 weeks before they become public) and bought an old lawnmower. then this project sleeped until christmas 1999. during the millenium panic here in germany, generators were offered that time at near to every shop you can imagine. i bought a 1.4 kW generator driven by a 3.5 HP motor (4 stroke) for about 130 $. i watched the geet newsgroup at onelist.com for a long time and recognised, that the main problem is leakage at the reactor. because of that, i planed to weld as many fittings and connections as possible to avoid leakage and bought the nessecary pipes and fittings. my goal is to achive operation with using heavy fuels like diesel and/or motor oil. i used pipes and fittings with dimensions like the "free geet plans". i read, when using heavier fuel, the fuel should be preheated and i designed a special bubbler as you can see at the drawing. i made the bubbler out of steel and welded it on top of the outer reactor pipe, where the temperature reaches its maximum. the rod has a length of 250mm. |

| results: | 20.03.2000 (first test run): i started the engine using the standard carburettor (gasoline) and the engine ran for about 3 minutes. the bubbler was filled with 50 ml pure diesel. i opend the air valve, while closing the carburettor valve. the engine stopped after 1 minute. after restart the carburettor was disabled (closed valve) 95 % and the system ran for about 15 minutes while experimenting with the other valves and stopped after the 50 ml diesel was burned completely. i recognised a leakage and reassembled the reactor. - the rod was very hot and had a blue/brown color. - the rod was not magnetic 21.03.2000

(second test run): 21.03.2000 (third test run): 21.03.2000 (fourth test run): further tests coming up: |

| remarks: | who can tell me, why the engine does not like

water? |

| pictures: |  picture 1 - overview of the test click image for 700x500, 140kb if you have any suggestions, comments or enhancement ideas to this device, please mail to bitbo@t-online.de

|

energy conversion systems - copyright '99 by bitbo@t-online.de |